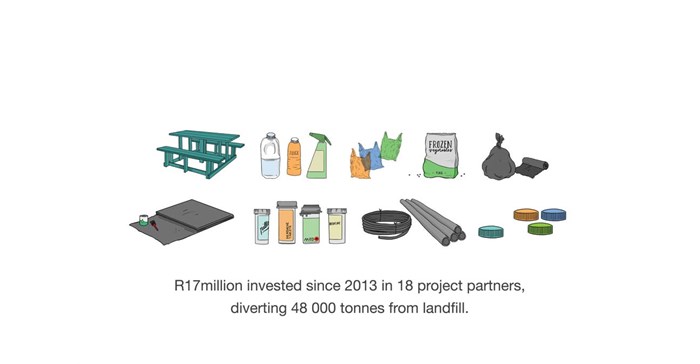

Since POLYCO, the non-profit polyolefin recycling company, started their operations a little over two years ago, they have already invested R17m into various separation, collection, sorting and recycling projects around South Africa, in order to increase the recycling rate.

The second round of projects this year, aimed at collectors, is in the final stages of evaluation and will be announced in the first week of August. This will see an estimated R5m being invested in the recycling industry.

"Three times per year, POLYCO issues a call for proposals from either collectors or recyclers who need funding support to take their businesses to the next level. To enable this process, POLYCO has developed a self-sustaining funding model. We believe in giving the successful candidates a 'hand-up', not a 'hand-out'," explains POLYCO CEO, Mandy Naudé.

Interest free loans

Approximately 80% of the funding support POLYCO provides takes the form of the interest free loans repayable over three years. The loan repayment funds are then re-loaned to other successful applicants. The remaining 20% of funding support is in the form of grants, redeemed against growth volumes.

"The more funding POLYCO loans to the recycling industry, the more funding income we are able to generate for further project support, without having to increase the recycling levy from converters," Naudé explains.

The company's third call for proposals in 2015 will commence on Monday, 17 August and is focused specifically on supply chain efficiency projects for mechanical recyclers. The final submission date for these proposals is 25 September 2015.

"We have budgeted approximately R9m to invest in projects that would grow recycling production volumes, resulting in the long term sustainable growth of the polyolefin plastics recycling industry," Naudé says.

Improving output

Common problems experienced by recyclers include supply chain bottle-necks due to material availability or logistic issues, and production constraints due to insufficient capacity or unreliable ageing equipment at their plants. In order to improve the output and quality of their products, recyclers need to upgrade their wash plant facilities or invest in new shredding, granulation, extrusion and testing equipment.

These are often very expensive investments to make in an industry that is known for its small margins and high operating costs. By partnering with POLYCO, however, these and many other improvements can be implemented cost-effectively.

"Successful applicants also enjoy the benefit of becoming part of the POLYCO network whereby they are referred business opportunities, connected to valuable networks, provided with media exposure and offered general business support and advice if required," Naudé says.

She warns, however, that applicants must prepare themselves for a rigorous selection process. "We do a thorough due diligence of each company we invest in, and require them to submit their business plan detailing the support required to be able to divert more polyolefin packaging materials from landfill. The rand/ton cost-effectiveness of the potential investment by POLYCO is an important consideration, and all funding contracts are linked to projected volume growth, which is the key objective," she concludes.