Subscribe & Follow

#AfricaMonth

In the news

Stainless steel shows high value potential in municipal water delivery

These findings have been revealed as part of a global collaboration between the Southern Africa Stainless Steel Development Association (sassda), the International Stainless Steel Forum (ISSF) and other stainless steel development associations from around the world.

Sassda executive director John Tarboton who attended the federation’s conference comments: “The successes of both the Tokyo and Seoul case studies reveal the opportunity of using stainless steel in water distribution and service pipes in South Africa to reduce maintenance costs and preserve our already strained water resources.

“There is a clear case of cost savings both on the treatment of water that is lost through leakage, as well as water that municipalities are unable to charge service fees for its distribution and use. There is also a finite amount of water we have to use in South Africa, making leak detection and water preservation vital for our future. Another factor is that, globally, 4% of electricity generation is used for pumping water. If one can reduce leakage, one can save electricity.”

A 30-year success story

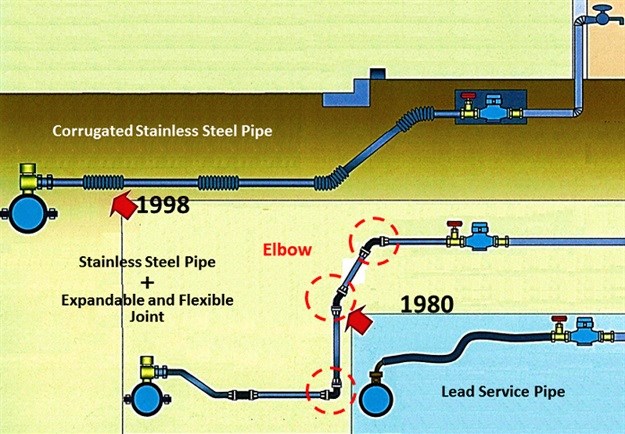

Facing comparative challenges to South Africa’s water recycling, filtration and distribution systems in the 1980s, Tokyo replaced a total of 27,000km of pipe with non-corrosive stainless steel piping nationally, reducing leakage and losses from 15.4% down to 2.2% in 2013.

Total cost reductions in Tokyo’s water distribution system have now reached the $480m mark with additional CO2 cost reductions in energy required for water recycling and water filtration pumps. The study also confirms that national stainless steel pipe replacements installed 30 years ago show no corrosion relating to chemical components in localised soils such as chloride concentrates. Similar studies show total reduction in leakage rates for Seoul by as much as 30%; Vietnam, which has reduced its leakage rate from 13% down to 7%, and Egypt from 29% down to 15% through the implementation of stainless steel piping.

The South African situation

Currently South Africa uses PVC and polyethylene piping which has a lifetime of approximately 20 years; a timeline that South Africa is currently facing as it undertakes a manifold service delivery challenge of leak detection and the replacement of damaged service water pipes across the country.

The importance of tightening up South Africa’s water supply infrastructure comes into sharp focus when one considers statistics cited in a Timeslive.co.za report last year, which stated that up to 40% of Johannesburg's water goes unaccounted for annually, costing the city R1.16bn in the year (ending June 30 2015). Of that about R851m of water was lost to leaks.

Delving into the reasons for these losses, Tarboton says the biggest issue currently causing leakage in municipal water distribution systems is seen via the smaller service pipes which pump water out from larger distribution pipes into high density areas such as cities and communities. It is leakages in this system that are extremely difficult to detect as leakage rates are typically low and go unnoticed.

A ‘flexible’ alternative

As the Tokyo case study reveals, with the use of corrugated stainless steel piping, the need for joints in the system is reduced, allowing the corrugated stainless steel pipes to maintain their strength, improve workability and extend the piping systems service life.

Says Tarboton, “The implementation costs of stainless steel could also be seen as a cost-saving opportunity, where initial outlay would be recouped through the savings gained in reduced energy costs and streamlined monitoring and billing systems. If finance companies could see fit to finance the implementation of stainless steel systems based on the savings gained from wasted and unauthorised water usage costs, a return on investment and total project costs could be built into the financing structure and provide a compelling initiative for South Africa’s water distribution services.

“We also have the ability and the technology available here in South Africa to manufacture the specified stainless steel pipes, something which could be a coup for the manufacturing industry in South Africa both at an incubator level and as a commercial enterprise. If our municipalities are already investing so heavily in leakage repairs and replacement piping, it makes sense to replace outdated pipe systems with stainless steel.”

Currently, the ISSF is embarking on a global awareness campaign following the success of the Tokyo case study and is on a mission to find the next country willing to grasp this opportunity, which it plans to actively contribute to, market and bring exposure to planning departments’ knowledge collateral.